Overview

How It's Made

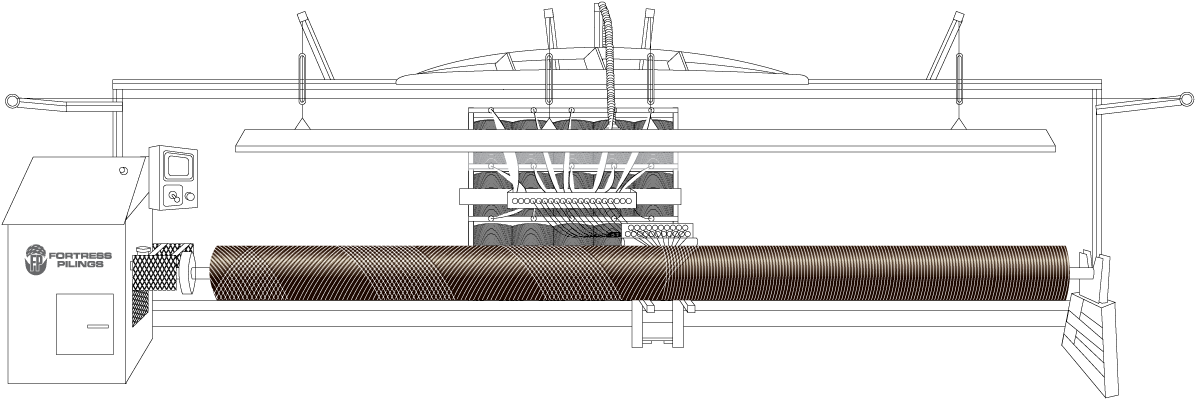

Fortress Pilings are fabricated using the filament winding process, whereby CNC equipment winds individual glass fibers at precise angles on a mandrel. Varying angles are used to ensure that each piling has excellent compressive and lateral strength, while being lighter and easier to handle than traditional piles.

Materials

Fortress Pilings are fully composite piles comprised of structural fiberglass protected by a premium gel coat finish. Fortress Pilings are designed to outperform and outlast pilings of traditional materials, while providing the most attractive finish available.

Synthetic inner liner – this barrier layer is specifically added so that Fortress Pilings may be filled with concrete or any other material. The barrier protects the fiberglass from the caustic efects of concrete.

Vinyl ester resin – Fortress Pilings use only 100% fire retardant vinyl ester resin. Never polyester, and never resin fillers.

1

2

3

4

Glass strands – each piling contains thousands of E-CR glass fibers, placed at precise angles by CNC equipment. Fortress Pilings never contain glass mats or cloths.

Gel coat exterior – Fortress Pilings are protected with a premium marine gel coat with UV protectants to provide the best weathering technology available.

Tap a circle for more information

Synthetic inner liner – this barrier layer is specifically added so that Fortress Pilings may be filled with concrete or any other material. The barrier protects the fiberglass from the caustic efects of concrete.

Vinyl ester resin – Fortress Pilings use only 100% fire retardant vinyl ester resin. Never polyester, and never resin fillers.

Glass strands – each piling contains thousands of E-CR glass fibers, placed at precise angles by CNC equipment. Fortress Pilings never contain glass mats or cloths.

Gel coat exterior – Fortress Pilings are protected with a premium marine gel coat with UV protectants to provide the best weathering technology available.